Weld Inspection: A Guide

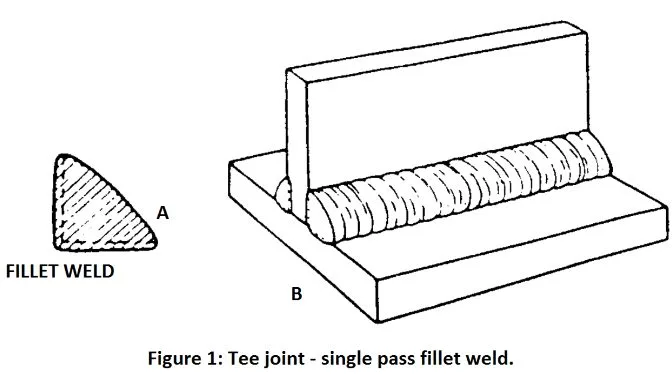

Weld inspection is a crucial process that involves examining welds to ensure they meet quality, strength, and safety standards. This evaluation helps prevent failures that could lead to serious consequences in industrial and structural applications. Trained professionals conduct weld inspections at various stages of the welding process—before, during, and after—to guarantee that the final product is reliable and safe. These checks are essential in industries where weld integrity can mean the difference between success and disaster. Whether it's metal, thermoplastics, or another material, welds play a vital role in construction, manufacturing, transportation, and more. Proper inspection ensures that both workers and the public remain safe from potential hazards caused by faulty welds.  Welding is a method used to join materials, typically metals, by melting them together and allowing them to cool into a single piece. This process is fundamental in creating strong and durable structures across many industries. In a weld, the base metal is melted and combined with a filler material, forming a weld pool. Once cooled, this creates a joint that is often stronger than the original materials. The skill and precision of welders and inspectors are essential in ensuring the integrity of these joints. Welding is used in a wide range of sectors, including aerospace, automotive, construction, energy, and shipbuilding. Each of these fields requires high-quality welds to maintain safety and functionality. Weld inspection is critical for maintaining safety throughout the entire welding process. It helps identify defects early on, preventing potential failures that could lead to accidents or equipment damage. Before welding begins, inspectors check materials, tools, and procedures to ensure everything is set up correctly. During the process, they monitor parameters like heat input and technique. After the weld is complete, they perform detailed checks to confirm the quality and compliance of the work. Annual inspections are also necessary for welds subjected to high stress, such as those in pipelines or heavy machinery. These checks help maintain long-term reliability and prevent costly repairs or failures. Welders face numerous risks, including exposure to intense heat, bright light, and harmful fumes. Protective gear like masks, gloves, and goggles is essential for their safety. Inspectors also ensure that all safety protocols are followed to minimize these dangers. Proper weld inspection should occur in three key phases: pre-weld, during-weld, and post-weld. Each stage plays a vital role in ensuring the quality and safety of the final product. This phase includes verifying that all materials, tools, and procedures are correct. Inspectors check blueprints, ensure proper preparation of the base metal, and confirm that the welder is qualified for the task. During the welding process, inspectors monitor factors such as heat input, welding speed, and technique. They look for signs of defects or inconsistencies that may affect the quality of the weld. After the weld has cooled, inspectors conduct thorough checks for discontinuities, cracks, or other flaws. They also verify that the weld meets design specifications and performs as expected under stress. Various techniques, both non-destructive and destructive, are used to evaluate the weld. These methods help identify hidden issues that may not be visible to the naked eye. There are several common types of welds, each suited for different applications. Understanding these types is essential for effective inspection and quality control. A butt joint is formed when two pieces of metal are joined along their edges. This type of weld is commonly used in piping systems and large structures due to its strength and simplicity. In a lap joint, two overlapping pieces of metal are fused together. This type of weld is ideal for joining materials of different thicknesses and is commonly used in sheet metal fabrication. A tee joint is created when one piece of metal is welded perpendicular to another. This type of weld is often used in structural steelwork and pipe fittings. Corner joints are similar to tee joints but form an L-shape instead of a T-shape. They are commonly used in box structures, frames, and containers. Edge joints are used when the edges of two pieces are parallel. While not as strong as other types, they are useful for providing additional support in certain structures. Understanding the different types of welds is crucial for inspectors, as it allows them to identify potential issues and ensure that the right welding method is used for each application. Several common welding defects can compromise the integrity of a weld. Identifying these issues early is essential for maintaining safety and performance. Burn-through occurs when the base metal is completely melted through, resulting in a hole in the weld. This defect is often seen in inexperienced welders and can significantly weaken the joint. Welds are vulnerable to corrosion over time, especially in harsh environments. Regular inspection helps detect early signs of degradation and prevents further damage. This defect occurs when the weld metal fails to fully fuse with the base metal at the root of the joint. It can result from improper welding technique or incorrect joint design. Lack of fusion happens when the weld metal does not properly bond with the base metal. This can lead to weak joints and potential failure under stress. Porosity refers to small gas pockets within the weld, which can reduce its strength and durability. It is often caused by excessive heat or contamination during the welding process. Slag inclusions occur when non-metallic residues become trapped in the weld. These can weaken the joint and lead to premature failure if not addressed. Undercutting happens when the base metal is burned away at the edge of the weld. This can reduce the strength of the joint and make it more prone to cracking. Identifying these defects is a key part of the weld inspection process, helping to ensure the safety and longevity of the final product. Weld inspection techniques can be broadly categorized into non-destructive and destructive methods. Both are used to assess the quality and integrity of a weld. These inspections do not damage the weld and are commonly used to detect surface and near-surface defects. Techniques include visual inspection, dye penetrant testing, magnetic particle testing, radiographic testing, and ultrasonic testing. This is the simplest and most cost-effective method. Inspectors visually examine the weld for obvious defects like cracks or burn-through. This method uses a colored or fluorescent dye to reveal surface cracks that may not be visible to the naked eye. This technique involves applying a magnetic field and ferromagnetic particles to detect surface and subsurface cracks. X-rays are used to inspect the internal structure of the weld, revealing hidden defects like porosity or slag inclusions. High-frequency sound waves are used to detect internal flaws in the weld, offering a precise and accurate method of inspection. [Related read: NDT (Non-Destructive Testing): A Complete Guide] Destructive inspections involve cutting or breaking the weld to analyze its internal structure. These tests are often used for certification, research, or quality assurance purposes. This method involves cutting a sample of the weld and etching it to reveal internal flaws or weaknesses. This test measures the tensile strength of a weld by applying force until it breaks, helping determine its load-bearing capacity. This test evaluates the ductility and flexibility of a weld by bending it to a specific radius and observing how it behaves under stress. A comprehensive weld inspection checklist ensures that all aspects of the welding process are thoroughly reviewed and verified. Weld inspectors rely on a variety of tools and equipment to perform their tasks effectively. The choice of equipment depends on the location and complexity of the weld. For example, a factory inspector may only need basic tools like a flashlight and magnifying glass, while an underwater inspector might require specialized gear such as a dive suit and remote-controlled cameras. Common equipment includes borescopes, gauges, flashlights, personal protective equipment, and radiographic machines. These tools help inspectors detect defects and ensure the weld meets all required standards. Drones are increasingly being used in weld inspection, particularly in hard-to-reach areas such as oil tanks, mines, or high-rise structures. Equipped with sensors and cameras, drones can access locations that are unsafe or difficult for humans to reach. With advancements in technology, drones equipped with ultrasonic or LiDAR sensors offer even greater accuracy and efficiency in identifying weld defects. This innovation is changing the way weld inspections are conducted, making them safer and more effective. Electric Cabin Scooter,Battery-Powered Vehicles,Disabled Scooter,Electric Cabin Scooter With Roof YUMBOMOBILITY LTD , https://www.yumbomobility.comWeld Inspection: A Comprehensive Guide

What Do Welds Do?

Why Is Weld Inspection Important?

The Three Stages of Weld Inspection

1. Pre-Weld Inspection

2. During-Weld Inspection

3. Post-Weld Inspection

Types of Welds

Butt Joint Welding

Butt joint weld

Butt joint weldLap Joint Welding

Lap joint weld | Source

Lap joint weld | SourceTee Joint Welding

Source

SourceCorner Joint Welding

Corner joint weld

Corner joint weldEdge Joint Welding

Edge weld | Source

Edge weld | SourceCommon Faulty Welds

Burn-through

Corrosion

Corrosion

CorrosionIncomplete Penetration

Lack of Fusion

Porosity

Porosity

PorositySlag Inclusions

Undercutting

Undercutting

UndercuttingTypes of Weld Inspection

Non-Destructive Weld Inspections

Visual Inspection

Liquid Penetrant Surface Crack Inspection

Liquid penetrant testing

Liquid penetrant testingMagnetic Particle Weld Inspection

Magnetic particle testing

Magnetic particle testingRadiographic Weld Inspection

Radiographic weld inspection

Radiographic weld inspectionUltrasonic Weld Inspection

Ultrasonic weld inspection

Ultrasonic weld inspectionDestructive Weld Inspections

Macro etch Weld Inspection

Macro etch destructive testing | Source

Macro etch destructive testing | SourceTransverse Tension Weld Inspection

Guided Bend Test Weld Inspection

Weld Inspection Checklist

Pre-Weld Inspection Checklist

During-Weld Inspection Checklist

After-Weld Inspection Checklist

Weld Inspection Equipment

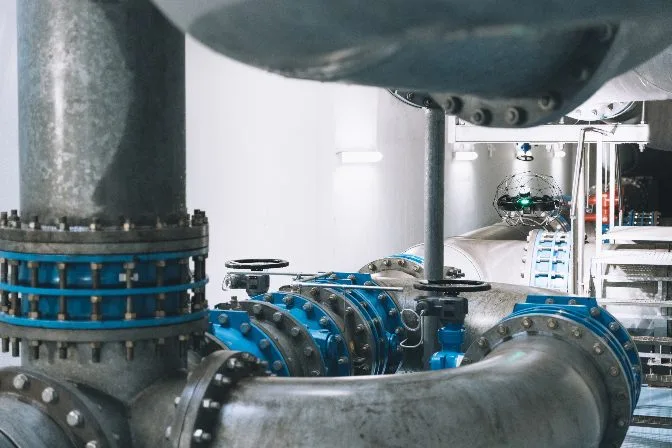

Drones as Weld Inspection Equipment

The Elios 3 drone inspecting water pipes

The Elios 3 drone inspecting water pipes