Exposing the truth behind manufacturers’ efficacy claims

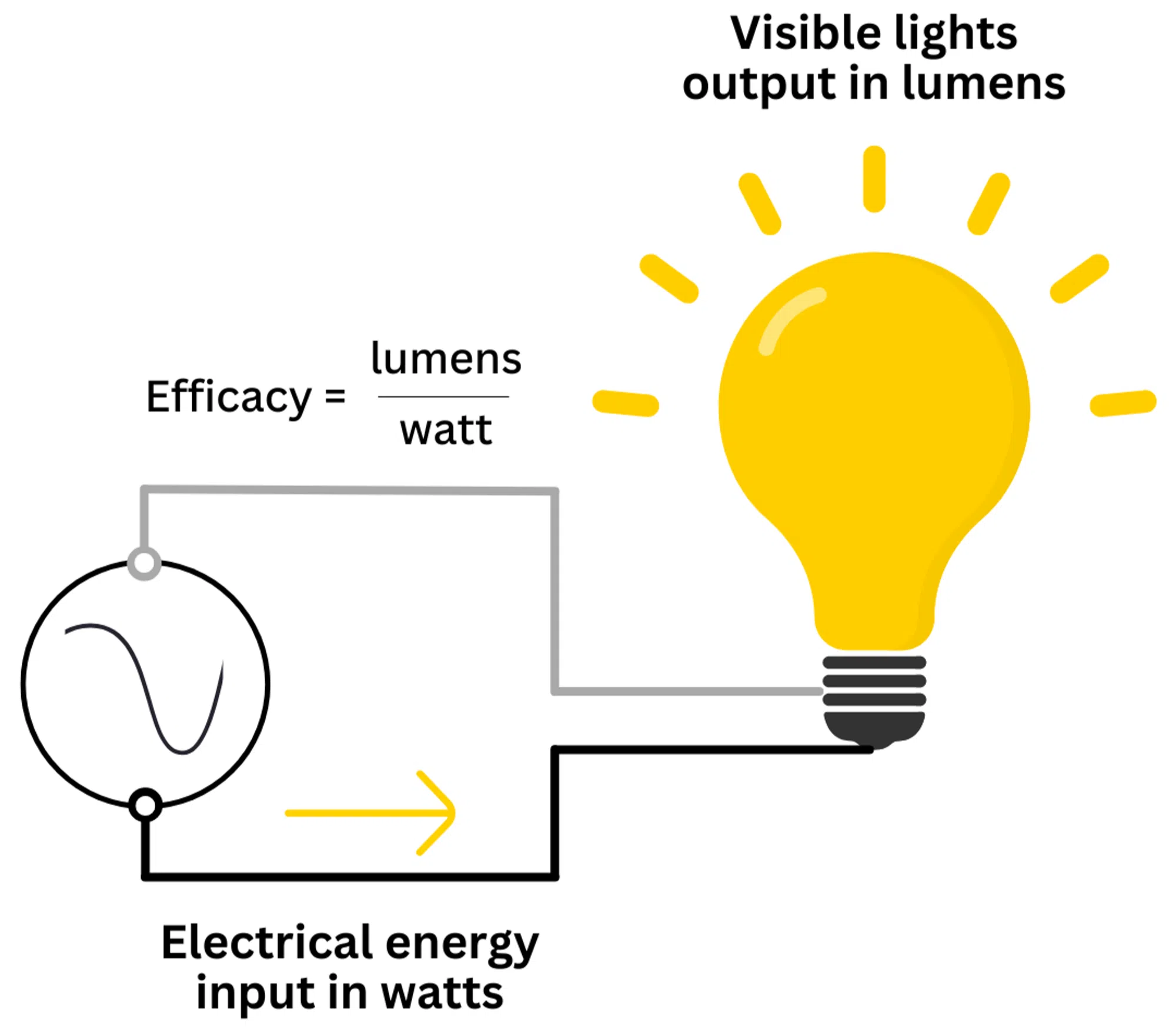

LED technology has revolutionized the lighting industry, offering significant advantages over traditional incandescent and fluorescent lamps. LEDs are more energy-efficient, provide superior light quality, and boast a longer lifespan, which has contributed to their rapid adoption across various sectors. According to the U.S. Department of Energy, LEDs accounted for 48% of installed lighting units in 2020, up from 8% in 2015 and just 1% in 2010.  As LED lighting gains popularity, competition among manufacturers intensifies to produce brighter and more efficient fixtures. In the lighting world, these qualities are often described using 'luminous efficacy,' which measures how effectively a light source converts electrical power into visible light. While this metric is crucial for evaluating a fixture's performance, it has become somewhat controversial as manufacturers strive to outdo each other.  One common practice among manufacturers is to measure the output of the bare LED chip instead of the entire fixture, including secondary optics like lenses. Although this approach yields impressive efficacy figures, it makes it challenging for specifiers and end-users to accurately compare products or determine the true output of a system.  In this article, we'll explore what efficacy really means, why it matters for solar lighting, how manufacturers sometimes mislead consumers with inflated claims, and some tips to help you distinguish genuine, high-quality products from those that merely appear impressive.   The Illuminating Engineering Society (IES) defines efficacy as "the total emitted luminous flux divided by the total source electrical input power." Typically expressed in lumens per watt (Lm/W or LPW), it quantifies how efficiently a light source transforms electricity into visible light. For instance, if a fixture emits 1500 lumens using 20 watts of power, the efficacy would be 75 LPW. Conversely, a fixture emitting 2500 lumens at 20 watts would have an efficacy of 125 LPW—considerably higher since it produces more light with the same power.   Although efficacy measures how efficient a light source is, it is not synonymous with "efficiency." These terms, while related, refer to distinct concepts. Efficacy focuses on the ratio of emitted visible light to consumed power, whereas efficiency concerns the proportion of light emitted by the fixture relative to its potential output. When comparing fixtures, efficacy is the more useful metric, though it’s important to note that these terms are often used interchangeably, despite their differences.    Given that most U.S. lighting infrastructure connects to the grid and is metered (meaning you pay for what you use), a higher-efficacy fixture clearly holds appeal. Generating more lumens per watt translates to greater illumination at lower costs, easing the burden on the grid while freeing up energy for other purposes. Reduced risks of blackouts, brownouts, and power surges further justify the preference for high-efficacy fixtures when lights are grid-connected.  However, what happens when lighting systems are powered by the sun, rendering energy costs irrelevant? Does energy efficiency still matter? Absolutely! A higher-efficacy fixture means producing more light with fewer watts. Lower wattage requirements translate into smaller solar panels and batteries, leading to cost-effective solutions. Additionally, manufacturers can optimize designs by reducing the Effective Projected Area (EPA) of their systems, suggesting cheaper poles, and making solar lighting viable even in high-latitude regions.   To maximize efficacy and attract customers, some manufacturers manipulate their product specifications. One prevalent tactic involves removing secondary optics such as lenses during testing, focusing solely on the unfiltered output of the LED chip. Without lenses, manufacturers can achieve remarkably high LPW figures because lenses moderate the chip’s output. While these numbers may seem impressive—say, 200 LPW—they are achieved under controlled laboratory settings and rarely reflect real-world performance once the chip is integrated into the fixture and installed in practical applications. It’s also worth noting that lenses play a vital role in distributing light evenly, so omitting them isn't feasible.  This wouldn't be problematic if manufacturers were transparent about their testing methods. Unfortunately, many fail to specify whether the efficacy listed in their technical documents refers to the LED chip alone or the full fixture, including the driver and lens. This ambiguity complicates efforts by prospective buyers to verify claims and compare products fairly.  The importance of LM-79 testing  Here's an insider tip: LM-79 testing. LM-79 is an IES-approved method for assessing the optical and electrical characteristics of solid-state lighting (LED) products, including total luminous flux, intensity, chromaticity, and yes, efficacy.  Crucially, LM-79 is only applicable to complete luminaires and cannot be used for individual components like LED packages or arrays. Using specialized equipment like integrating spheres and goniophotometers, LM-79 captures a snapshot of the system's capabilities at a specific moment under consistent conditions, enabling direct comparisons between manufacturers and models. This is exactly what you want!   The second essential fact about LM-79 is that it is the sole test providing reliable data on lumen output and efficacy. Other IES tests, such as LM-80 and TM-21, focus on lumen depreciation, color shifts, and lifespans, but they apply to components (like LED chips). As NVC Lighting notes, "For an end user, specifier, or installer to evaluate the relative merits of an LED lamp or lighting fixture, an LM-79 test report is recommended."  Wondering how to confirm whether a product underwent LM-79 testing? Technical datasheets and IES files are excellent starting points. These resources are usually downloadable from manufacturers' websites, and a quick Ctrl+F search for 'LM-79' should yield answers. We reviewed three Tier 1 street lighting products and found LM-79 reports easily accessible for all three. (Tier 1 manufacturers like Acuity and Cree typically adhere to stricter testing protocols than smaller firms.)   Other red flags to watch for  Beyond missing LM-79 certification, there are additional signs to alert you to unrealistic efficacy claims. First, look out for ratings that fall outside the typical range of reputable manufacturers. Based on our examples, you'll notice that most reputable products hover around 120 to 160 LPW depending on their performance tier. If a system claims significantly higher or lower figures, proceed cautiously. Ask the manufacturer how they reached these numbers, whether they pertain to the fixture or the chip, and whether third-party verification exists.  Another warning sign is consistency in efficacy regardless of lumen package size. For instance, if a manufacturer claims a fixture maintains an efficacy of 150 LPW at both 20W and 100W, something is off. Lower wattages should yield higher efficacies, while higher wattages tend to decrease them. Manufacturers consistently claiming identical efficacies across varying outputs raise red flags.  Making informed purchase decisions Understanding efficacy and leveraging it as a benchmark is vital for making smart lighting purchases. However, not all manufacturers measure efficacy identically—or even label it the same way. Independent tests like LM-79 standardize measurement practices, simplifying comparisons between models and brands, and helping you choose a system suited to your project's needs.  If you're unable to find necessary details on a manufacturer's website or technical documentation, consider asking these questions:  Got a question for us—about efficacy or anything else? Our team of solar experts is ready to assist and eager to hear from you.  Other Series Of Plate Heat Exchangers Other Series Of Plate Heat Exchangers,Other Series Of Brazed Plate Heat Exchanger,Other Series Of Plate Type Heat Exchanger,Plate And Shell Heat Exchanger Siping Juyuan Hanyang Plate Heat Exchanger Co., Ltd , https://www.tj-heatexchange.com

What is efficacy?

Why is it important for solar lighting?

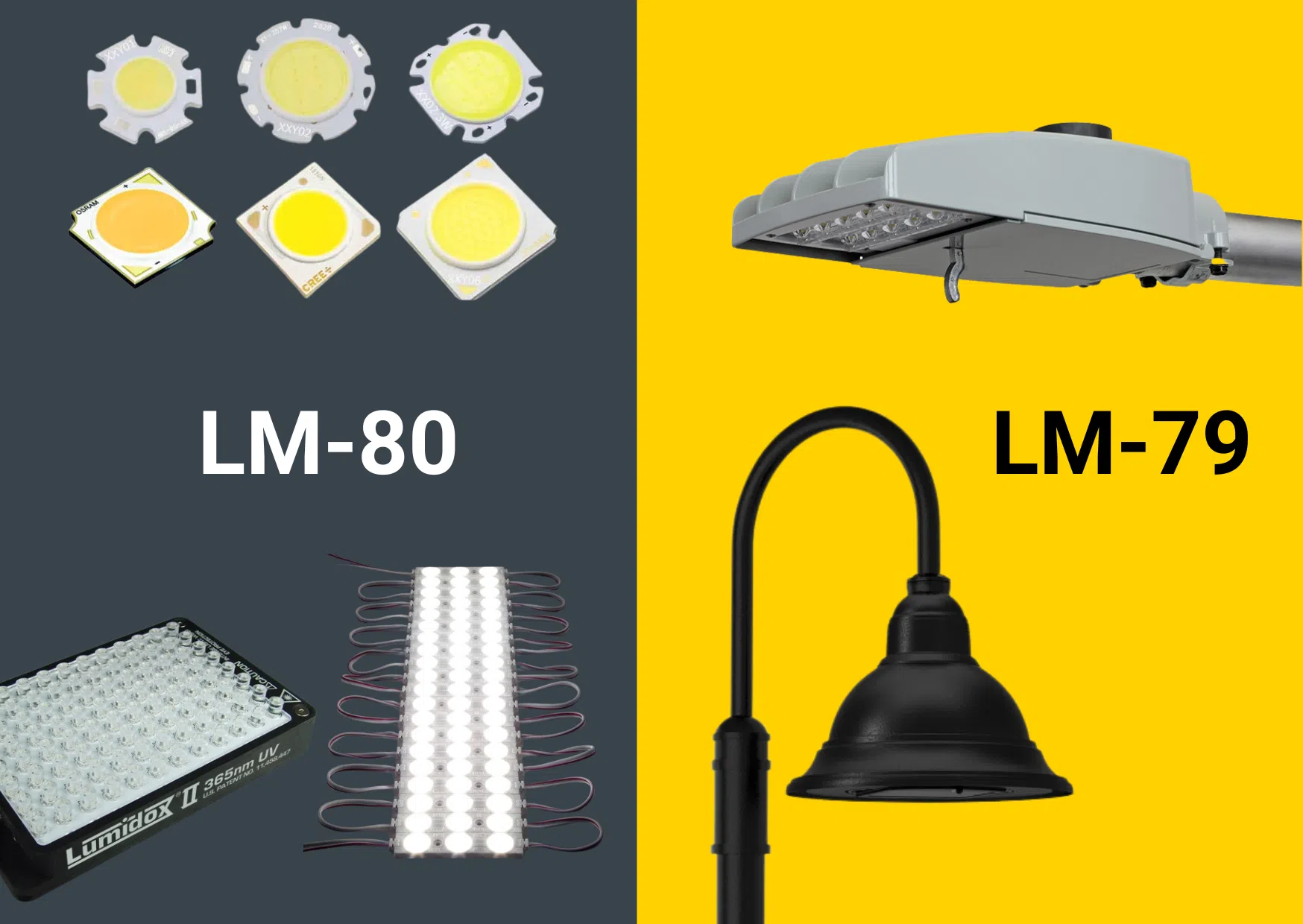

How do manufacturers exaggerate efficacy?