As the technical advisor to asset owners, Pure Power frequently assists clients in making critical decisions about repairing, repowering, or optimizing the performance of their operational solar assets. In this capacity, our team of engineers often relies heavily on record drawings provided by the installation contractor once the project is completed and accepted. However, when these record drawings fail to align with the actual as-built conditions, project owners face the risk of incurring unnecessary and avoidable expenses.

---

### What Are As-Built Drawings?

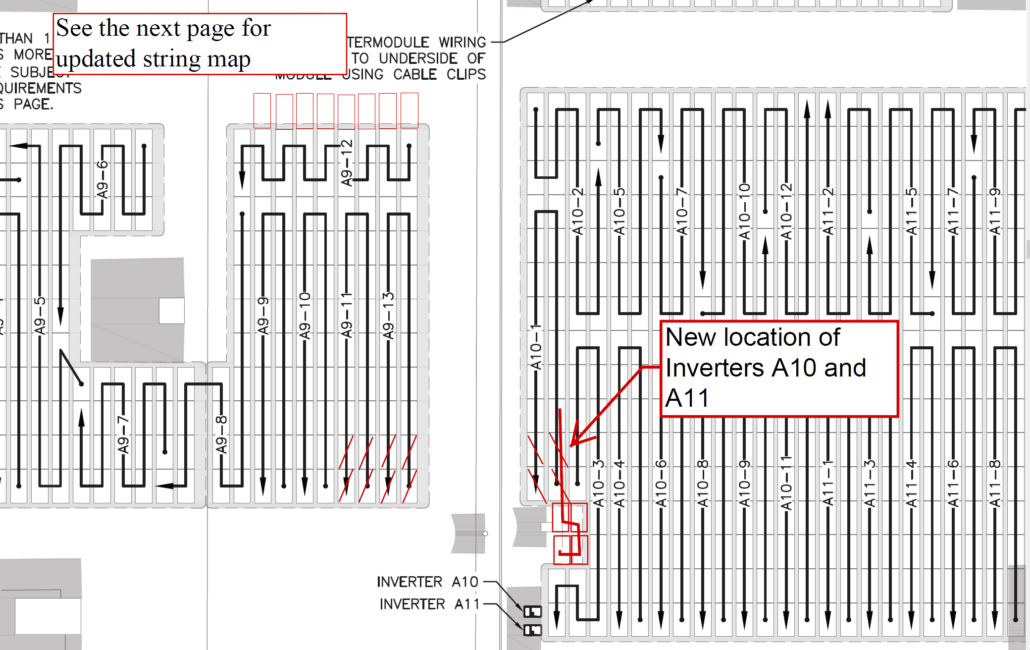

As-built drawings are updated versions of the original engineering construction drawings, representing the real-world conditions post-construction. During the building phase, the installing contractor is tasked with documenting any discrepancies between the official construction drawings and the actual site conditions. These informal change-tracking documents are commonly referred to as "red-line drawings." They capture significant modifications made throughout the construction process. Once the project wraps up, the contractor must deliver a finalized set of drawings incorporating these red-line updates. The as-built drawings serve as a historical record of these changes.

### Who Is Responsible for As-Built Drawings?

Even after the project becomes operational, the ultimate responsibility for ensuring the accuracy of as-built drawings falls on the owner. This is an ongoing process involving multiple parties:

- **Installing Contractor**: During construction, the contractor is primarily responsible for keeping the as-built drawings updated. This is both a professional best practice and a form of due diligence since they are accountable for any changes approved by the developer, owner, or financier. Most contracts explicitly require the contractor to deliver accurate as-built drawings upon project closure.

- **Independent Engineer**: Some contractors lack the resources or processes to fully document all changes accurately. In such cases, owners may opt to hire an independent engineer to verify the actual conditions before project acceptance. A third-party inspection helps prevent inaccuracies in contractor drawings from complicating future asset management tasks post-completion.

- **Asset Manager**: Assuming the as-builts are correct at project commissioning, owners still need to ensure they stay updated during operations and maintenance. Many owners delegate these responsibilities to an asset manager, who has a strong incentive to keep project drawings current to maximize operational efficiency.

---

### Best Practices for Project Owners and Operators

Inaccurate as-built drawings can lead to costly mistakes and inefficiencies during operations. Without reliable drawings, stakeholders cannot make informed decisions about design enhancements, component replacements, or repairs. Here are some practical tips to ensure your project as-builts are precise:

- **Accuracy During Construction**: Every solar project contract should mandate the submission of as-built drawings at completion. To guarantee accuracy, include provisions for pre-acceptance engineering oversight. The owner’s engineer should confirm, as part of the final punch list, that the contractor delivers compliant as-builts.

- **Update Legacy Systems**: Old drawing sets become increasingly unreliable over time. Before undertaking capital improvements on legacy systems, owners should conduct inspections to verify the currency and accuracy of existing drawings. The cost of updating drawings is minimal compared to the potential losses from incorrect decisions based on outdated information.

- **Digitize from the Start**: If redlines begin as hand-drawn annotations on paper, there’s always a risk of miscommunication or omissions reaching the digital version. We recommend maintaining redlines and as-builts digitally from day one. This approach significantly boosts the chances of capturing all changes accurately in the latest drawings.

- **Implement Revision Control**: Once construction documents are issued, every subsequent change enters a formal revision cycle starting with the redlines. This process doesn’t stop after commissioning; it continues as long as the solar project operates. The asset manager or owner-operator must establish robust and transparent revision protocols to manage files, documents, and versions. Maintaining a continuous audit trail of revisions enhances operational efficiency and reduces long-term operating costs.

By adhering to these guidelines, project owners can mitigate risks, optimize performance, and achieve greater value from their solar assets.

Fan Clutch

Here you can find the related products in Fan Clutch, we are professional manufacturer of cooling fan clutch,electric fan clutch, ac fan clutch,engine fan clutch, fan clutch price , car fan cluth ect.

We focused on international export product development, production and

sales. We have improved quality control processes of Fan Clutch to

ensure each export qualified product.

If you want to know more about

the products in Fan Clutch, please click the product details to view

parameters, models, pictures, prices and other information about cooling fan clutch,electric fan clutch, ac fan clutch,engine fan clutch, fan clutch price , car fan cluth.

Whatever

you are a group or individual, we will do our best to provide you with

accurate and comprehensive message about Fan Clutch!

Fan Clutch Tool,Fan Clutch Assembly,Fan Clutch Autozone,Fan Clutch Adapter

Guangzhou Taixin Auto parts Trading Co., Ltd. , https://www.hyundai-autopart.com