A nut should always match the bolt's specifications to ensure optimal performance. When properly matched, they form a robust connection capable of enduring significant stress and strain over time. This compatibility ensures the system remains secure under extreme conditions, effectively supporting heavy loads.

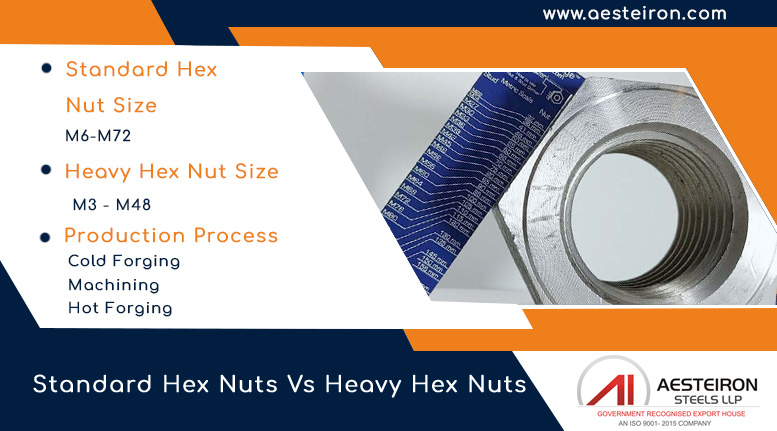

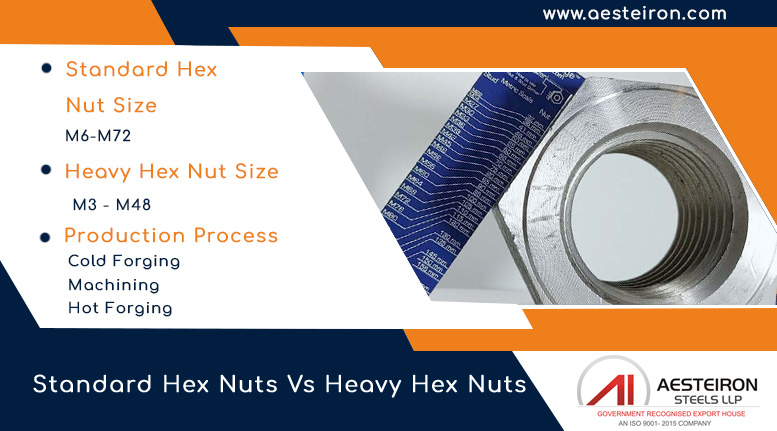

Improper fasteners can lead to catastrophic failures, potentially causing severe damage or endangering lives. For instance, mismatched nuts and bolts may loosen or break under pressure, leading to mechanical collapse. Below, we’ll explore the differences between standard hex nuts and heavy hex nuts to help you choose the right option for your needs.

Table of Contents

- Standard Hex Nuts vs Heavy Hex Nuts

- Dimension Chart of Heavy Hex Nut

- Weight Chart of Hex Nuts

- Specifications of SS Heavy Hex Nuts

- Coating Process of Heavy Hex Nuts

- Applications of Heavy Hex Nuts

- Benefits of Heavy Hex Bolts

- Standards and Grades of Hex Nuts

- Differences Between Standard and Heavy Hex Nuts

- Mechanical Properties of Heavy Hex Nuts vs Standard Hex Nuts

- Advantages of Steel Heavy Hex Nuts

- Key Features of Standard and Heavy Hex Nuts

Standard Hex Nuts vs Heavy Hex Nuts

|

Standard Hex Nuts |

Heavy Hex Nuts |

|

|

|

| Shape |

Same shape as heavy hex nuts |

Same shape as standard hex nuts |

| Width Across Flats and Corners |

Smaller for the same nominal size |

Larger for the same nominal size |

| Thickness |

Thinner for the same nominal size |

Slightly thicker for the same nominal size |

| Diameter Across Flats |

Smaller |

1/8†larger than standard hex nuts |

| Tool Requirements |

Standard wrenches and sockets |

Larger wrenches and sockets required |

| Proof Load Strength |

Lower compared to heavy hex nuts |

Higher compared to standard hex nuts |

Check Dimensions and Weight Chart of Heavy Hex Nut

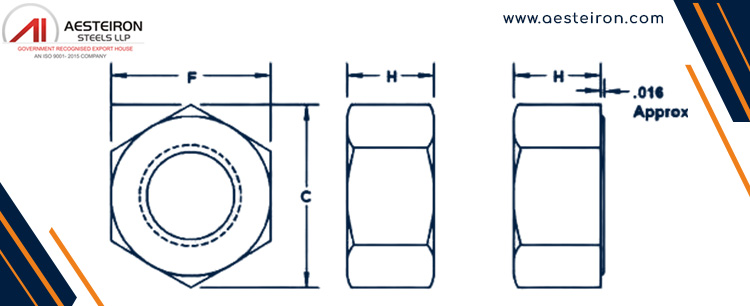

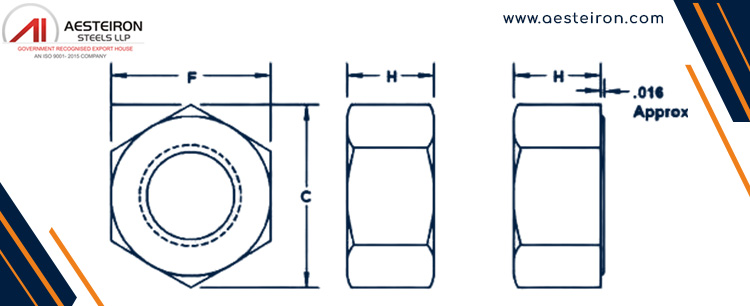

Heavy hex nuts are generally larger and thicker than standard hex nuts. They are commonly used for high-strength bolts and applications requiring greater durability. Understanding their dimensions ensures proper fitment and structural integrity, preventing issues like misalignment or failure.

Weight is also crucial in industries where safety and structural stability are paramount, such as construction and engineering. Knowing the exact weight helps in planning and executing projects efficiently.

Dimension Chart of Heavy Hex Nut

| Bolt Diameter |

1â„2 |

5â„8 |

3â„4 |

7â„8 |

13â„8 |

11â„2 |

1 |

11â„8 |

11â„4 |

15â„8 |

13â„4 |

31â„4 |

31â„2 |

2 |

21â„2 |

23â„4 |

3 |

33â„4 |

4 |

| F |

Width Across Flats |

Basic |

7â„8 |

11â„16 |

11â„4 |

17â„16 |

23â„16 |

23â„8 |

15â„8 |

113â„16 |

2 |

29â„16 |

23â„4 |

5 |

53â„8 |

31â„8 |

37â„8 |

41â„4 |

45â„8 |

53â„4 |

61â„8 |

| Max |

0.875 |

1.062 |

1.25 |

1.438 |

2.188 |

2.375 |

1.625 |

1.812 |

2 |

2.562 |

2.75 |

5 |

5.375 |

3 |

3.875 |

4.25 |

4.625 |

5.75 |

6.125 |

| Min |

0.85 |

1.031 |

1.212 |

1.394 |

2.119 |

2.3 |

1.575 |

1.756 |

1.938 |

2.481 |

2.662 |

4.838 |

5.2 |

3 |

3.75 |

4.112 |

4.475 |

5.562 |

5.925 |

| C |

Width Across Corners |

Max |

1.01 |

1.227 |

1.443 |

1.66 |

2.526 |

2.742 |

1.876 |

2.093 |

2.309 |

2.959 |

3.175 |

5.774 |

6.207 |

4 |

4.474 |

4.907 |

5.34 |

6.64 |

7.073 |

| Min |

0.969 |

1.175 |

1.382 |

1.589 |

2.416 |

2.622 |

1.796 |

2.002 |

2.209 |

2.828 |

3.035 |

5.515 |

5.928 |

3 |

4.275 |

4.688 |

5.102 |

6.341 |

6.755 |

| H |

Thickness |

Basic |

31â„64 |

39â„64 |

47â„64 |

55â„64 |

111â„32 |

115â„32 |

63â„64 |

17â„64 |

17â„32 |

119â„32 |

123â„32 |

33â„16 |

37â„16 |

131â„32 |

229â„64 |

245â„64 |

261â„64 |

311â„16 |

315â„16 |

| Max |

0.504 |

0.631 |

0.758 |

0.885 |

1.378 |

1.505 |

1.012 |

1.139 |

1.251 |

1.632 |

1.759 |

3.252 |

3.506 |

2 |

2.505 |

2.759 |

3.013 |

3.76 |

4.014 |

| Min |

0.464 |

0.587 |

0.71 |

0.833 |

1.31 |

1.433 |

0.956 |

1.079 |

1.187 |

1.556 |

1.679 |

3.124 |

3.37 |

2 |

2.401 |

2.647 |

2.893 |

3.616 |

3.862 |

| Weight(lbs.) |

0.07 |

0.12 |

0.2 |

0.3 |

1.02 |

1.31 |

0.43 |

0.59 |

0.79 |

1.62 |

2.04 |

11.94 |

15.26 |

3 |

5.64 |

7.38 |

9.5 |

18.12 |

21.8 |

| Part Numbers |

A563A |

Import |

Plain |

11729 |

11731 |

11733 |

11735 |

11743 |

11745 |

11737 |

11739 |

11741 |

17750 |

11747 |

18395 |

18495 |

# |

11753 |

15864 |

15863 |

– |

11755 |

| Galv. |

11730 |

11732 |

11734 |

11736 |

11744 |

11746 |

11738 |

11740 |

11742 |

17751 |

11748 |

– |

– |

# |

11754 |

16041 |

16042 |

– |

11756 |

| A1942H |

Domestic |

Plain |

– |

16358 |

16360 |

16362 |

16374 |

16378 |

16364 |

16366 |

16370 |

16380 |

16384 |

– |

– |

# |

16398 |

16400 |

16402 |

– |

16404 |

| Galv. |

– |

16359 |

16361 |

16363 |

– |

– |

16365 |

– |

– |

16381 |

16385 |

– |

– |

# |

16399 |

16401 |

16403 |

– |

16405 |

| Import |

Plain |

11761 |

11763 |

11765 |

11767 |

11775 |

11777 |

11769 |

11771 |

11773 |

11779 |

12549 |

– |

– |

# |

12553 |

12555 |

12601 |

– |

– |

| Galv. |

11762 |

11764 |

11766 |

11768 |

11776 |

11778 |

11770 |

11772 |

11774 |

11780 |

12550 |

– |

– |

# |

12554 |

12556 |

12602 |

– |

– |

| A563DH |

Domestic |

Plain |

16356 |

– |

– |

– |

– |

– |

– |

– |

16380 |

16384 |

– |

– |

# |

16398 |

16400 |

16402 |

– |

16404 |

| Galv. |

18345 |

18346 |

18347 |

18348 |

16375 |

16379 |

18349 |

16367 |

16371 |

16381 |

16385 |

– |

– |

# |

16399 |

16401 |

16403 |

– |

16405 |

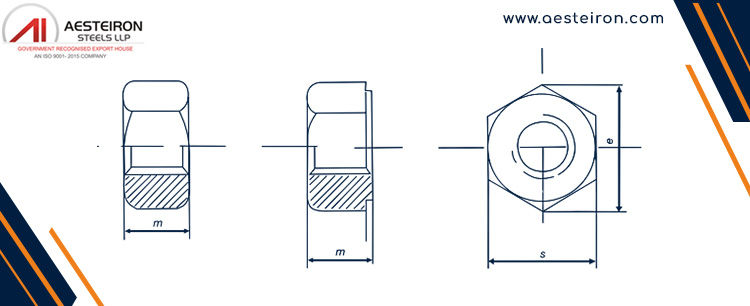

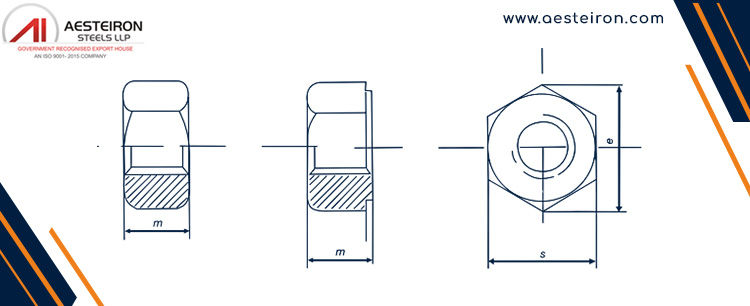

Weight Chart of Hex Nuts

| METRIC RANGE – DIMENSION (mm) AND WEIGHT (Kg) PER 100 PIECES |

| d |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

M42 |

M45 |

M48 |

M52 |

M56 |

M60 |

M64 |

M68 |

M72 |

M76 |

M80 |

M85 |

| S |

Min |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

26.67 |

29.67 |

31.61 |

35.38 |

40.38 |

45.38 |

49.26 |

54.26 |

59.26 |

64.26 |

69.26 |

74.26 |

79.26 |

84.15 |

89.13 |

94.13 |

99.13 |

104.13 |

109.13 |

114.13 |

119.13 |

| Max |

13 |

17 |

19 |

22 |

24 |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

115 |

120 |

| e |

Min |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

30.14 |

33.53 |

35.72 |

39.98 |

45.63 |

51.28 |

55.8 |

61.31 |

66.95 |

72.61 |

78.26 |

83.91 |

89.56 |

95.07 |

100.72 |

106.37 |

112.02 |

117.67 |

123.32 |

128.97 |

134.62 |

| Max |

15 |

19.6 |

21.9 |

25.4 |

27.7 |

31.1 |

34.6 |

36.9 |

41.5 |

47.3 |

53.1 |

57.7 |

63.5 |

69.3 |

75 |

80.8 |

86.5 |

92.4 |

98.1 |

103.9 |

109.7 |

115.5 |

121.25 |

127 |

132.8 |

138.6 |

| m |

Min |

7.64 |

9.64 |

11.57 |

13.57 |

15.57 |

17.57 |

19.48 |

21.48 |

23.48 |

26.48 |

29.48 |

32.38 |

35.38 |

38.38 |

41.38 |

44.38 |

47.38 |

51.38 |

55.26 |

59.26 |

63.26 |

67.26 |

71.26 |

75.26 |

79.26 |

84.13 |

| Max |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

45 |

48 |

52 |

56 |

60 |

64 |

68 |

72 |

76 |

80 |

85 |

| WEIGHT |

0.65 |

1.43 |

2.03 |

3.14 |

4.05 |

5.82 |

7.91 |

9.49 |

13.7 |

20 |

28.4 |

36.1 |

48.3 |

62.3 |

79.5 |

98.8 |

122 |

147 |

177 |

208 |

245 |

284 |

327 |

374 |

425 |

483 |

Specifications of SS Heavy Hex Nuts

- Metric Size Range: M3 – M48

- Imperial Size: 3/8 to 8"

- Surface Finish: Cadmium zinc plated, Galvanized, Hot dip Galvanized, Nickel Plated, Blackening

- Material: Stainless steel, Carbon, Alloy Steel, API 5L Copper, Duplex, Titanium

- Threads: Metric, BSW, BSF, UNC, UNF

- Test Certificates: EN 10204 / 3.1B, Raw Materials Certificate, Third Party Inspection Report, 100% Radiography Test Report

- Applications: Heavy Industry, Marine, Ship Building, Oil & Gas Projects

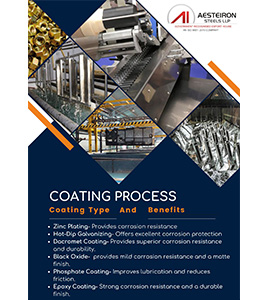

Coating Process of Heavy Hex Nuts

- PTFE Coated

- Hot Dip Galvanized

- Yellow Zinc Plated

- Blue Zinc Plated

- Black Zinc Plated

- Zinc Cobalt Plated

- Aluminum Zinc Flake Coated

- Black Phosphate

- Zinc Plated

- Nickel Plated

Heavy Hex Nuts Are Typically Made From High-grade Steel and Used With Heavy Bolts

High-grade steel provides heavy hex nuts with unparalleled strength and longevity, especially in applications involving high bending loads and pressure. Their combination with heavy bolts ensures a robust and resilient connection, safeguarding structures and equipment against adverse conditions.

When it comes to industrial applications, heavy hex nuts are indispensable due to their ability to withstand immense forces without compromising performance.

Applications of Heavy Hex Nuts

| Application Area |

Uses and Examples |

| Construction |

- Structural Steel

- Heavy Machinery |

| Transportation |

- Railroads

- Automotive |

| Industrial |

- Machinery

- Pipelines |

| Energy Sector |

- Oil and Gas

- Renewable Energy |

| High-Strength Bolting |

- High-Stress Fasteners |

| Mining |

- Mining Equipment |

| Marine Applications |

- Shipbuilding

- Offshore Platforms |

Key Benefits of Heavy Hex Bolts

- Increased Strength: Capable of handling significantly higher loads and stresses compared to standard hex nuts.

- Durability: More resistant to deformation under load.

- Better Bearing Surface: Provides a larger surface area for better load distribution.

Torque Chart for Standard Hex Nuts

Standard hex nuts are designed with specific diameters and thread pitches to ensure compatibility with bolts or screws. A torque chart specifies the ideal tightening values for hex nuts, ensuring the correct clamping force in bolted joints. Proper torque is vital for maintaining joint strength and avoiding issues like loosening or over-tightening.

Standards and Grades of Hex Nuts

| Material |

Standards |

Grades |

| Stainless Steel Hex Nuts |

ASTM / ASME A/SA 193 / 194 |

B 8 (304), B 8C (SS 347), B 8M (SS 316), B 8 T (SS 321), A 2, A 4 |

| Nickel Alloy Hex Nuts |

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 |

UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3) |

| Alloy Steel Hex Nuts |

ASTM / ASME A/SA 193 / 194 GR |

B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

Standard Hex Nuts Have Smaller Widths Compared to Heavy Hex Nuts

Heavy hex nuts are wider across the flats and corners and slightly thicker than standard hex nuts. Due to their robust design, they can handle higher pressures compared to standard hex nuts.

Differences Between Standard and Heavy Hex Nuts

Steel Rebar

Shandong Yuzhong Steel Co.,Ltd. , https://www.cnyzsteel.com