Identifying chimney tower faults with the Elios 3 at a cement plant

A cement plant’s chimney stack, standing at 120 meters tall, showed signs of a visible fault in February 2023. While the engineers were aware of the potential risks associated with this anomaly, they faced the daunting task of inspecting such a towering structure. Traditionally, this kind of inspection would require a crane, which could take days to set up and dismantle, costing around 30,000 euros. Instead, the plant turned to the Elios 3, a specialized drone designed for confined spaces, to conduct a comprehensive inspection in just one hour. The drone captured 4K video footage and performed a LiDAR scan, providing invaluable data for detailed 3D analysis. Access Working at heights of 120 meters poses significant risks, often requiring crane operations. The Elios 3 eliminated the need for such risky operations, providing safe access and critical data in just an hour. Speed Traditional inspections could take an entire day, but the Elios 3 completed its inspection in just 60 minutes. This represents an 8-fold increase in efficiency compared to conventional methods. Cost Savings Using the Elios 3 instead of a crane saved the plant 30,000 euros. Moreover, the rapid deployment of the drone minimized downtime, saving both time and money. Visualization The 3D model generated from the drone’s data allowed for swift decision-making and served as a valuable case study for future reference.  In 2022 alone, global cement production reached 4.1 billion tons. Cement is one of the most crucial construction materials, and any disruption in its supply chain can lead to severe consequences. Cement plants therefore face the challenge of balancing high production demands with the need for meticulous maintenance of their complex machinery.

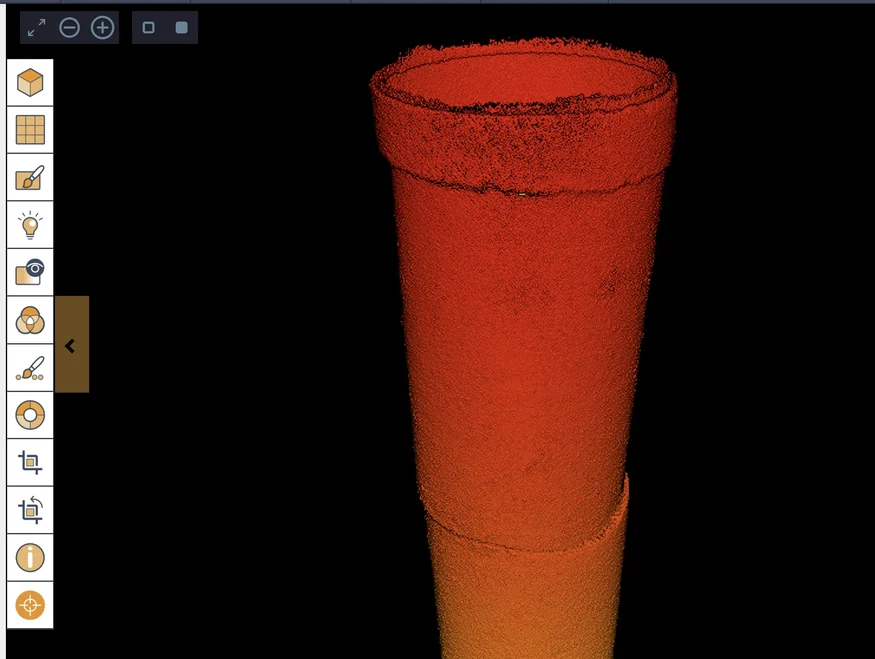

One of the critical components of a cement plant is the chimney stack, which releases hot gases and waste products from the kilns. These stacks, measuring 120 meters tall and 4 meters wide, are essential to the plant’s infrastructure. They consist of an inner and outer layer of concrete, designed to withstand temperatures as high as 150 degrees Celsius. Despite their durability, these structures require careful monitoring to prevent catastrophic failures.

When an engineer noticed a slight tilt at the top of the chimney stack, it became clear that immediate action was necessary to avoid potential hazards and ensure continuous production. The chimney stack at this cement plant was linked to two kilns, which undergo maintenance annually—each kiln during different seasons. This staggered schedule ensures minimal downtime for production. However, the chimney itself is rarely inspected due to its structural integrity and lack of routine maintenance needs. When a fault does occur, it can severely disrupt operations.

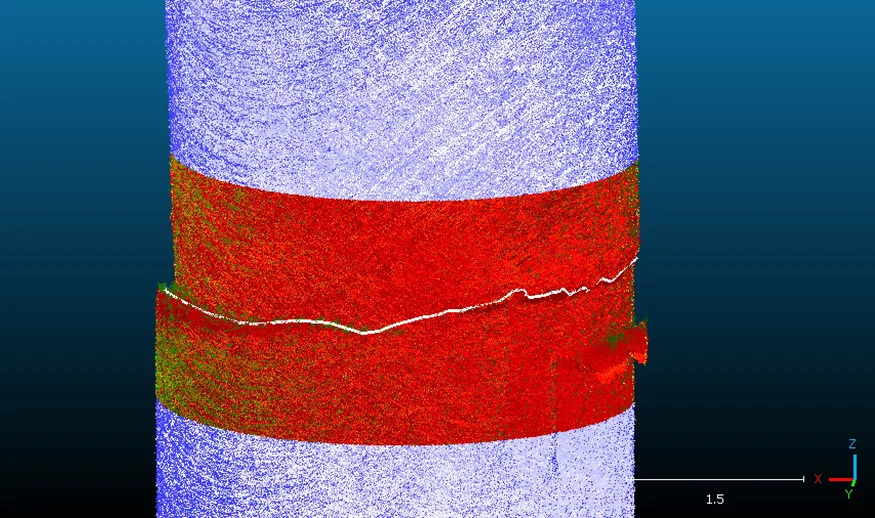

This particular chimney stack was 120 meters tall and had an inner and outer concrete layer, each supporting the other against the extreme heat from the gases. The top portion of the stack had started to show signs of subsidence, raising concerns about its stability. The risk of collapse or further damage was high, making prompt intervention essential. Realizing the urgency, the plant’s drone pilot swiftly deployed the Elios 3 to perform an inspection. Traditional methods would have required a crane setup, taking at least a day and costing upwards of 30,000 euros. The Elios 3, however, was ready to fly within minutes, completing the entire inspection in just one hour. During this time, it captured high-definition video footage and conducted a precise LiDAR scan, creating a detailed 3D model of the chimney’s current state. The Elios 3’s innovative design allowed it to navigate the confined space of the chimney stack effectively. Its LiDAR technology ensured accurate mapping, even in challenging environments. Unlike previous methods that relied heavily on guesswork, the Elios 3 provided clear, actionable insights, enabling engineers to plan maintenance with precision. Following the inspection, the raw LiDAR data was processed using GeoSLAM Connect 2.3 to generate a high-density point cloud. This data was then transferred to CloudCompare for further analysis. Cross-sectioning the point cloud revealed alarming findings: the inner sleeve of the chimney stack was subsiding in the uppermost 7 to 10 meters. Concrete had collapsed and shifted 150mm to the east, causing the top 7.5 meters of the stack to lean at a 4-degree angle. The visualizations clearly demonstrated the extent of the damage, prompting immediate action. Engineers quickly devised a maintenance plan to replace the compromised section of the inner tube. The 3D model provided precise measurements, streamlining the replacement process and eliminating guesswork. The maintenance team began by removing the damaged section of the inner tube, which weighed approximately 7 tons. Despite its size, the team managed to safely remove it in five days. Following this, they cleaned and inspected the outer tube, which had been concealed beneath the collapsing inner section. This phase took an additional day. Finally, the new section of concrete was installed, completing the repair in four days. Thanks to the Elios 3, the entire repair process was completed in just two weeks, significantly reducing downtime and saving the plant considerable resources. The drone inspection not only identified the problem early but also facilitated efficient planning and execution of the repairs. Moving forward, this project will serve as a case study for the cement industry, highlighting the importance of proactive inspections and the benefits of adopting advanced technologies like the Elios 3. By cutting the inspection and repair process by nearly three days compared to traditional methods, the Elios 3 proved its value in enhancing operational efficiency and safety. The plant now plans to integrate drone inspections into its regular maintenance routines, ensuring ongoing reliability and productivity. Discover more about the Elios 3 and its applications in various industries. Clutch Slave Cylinder For SUZUKI ZHEJIANG BENTENG INTELLIGENT BRAKE SYSTEM CO.,LTD , https://www.cnnakol.comIdentifying Chimney Tower Faults With The Elios 3 At A Cement Plant

Benefits In A Nutshell

Introduction

Understanding The Problem

Solution: Drone Inspection With The Elios 3

Inspection Results

Implementation And Outcome