Identifying chimney tower faults with the Elios 3 at a cement plant

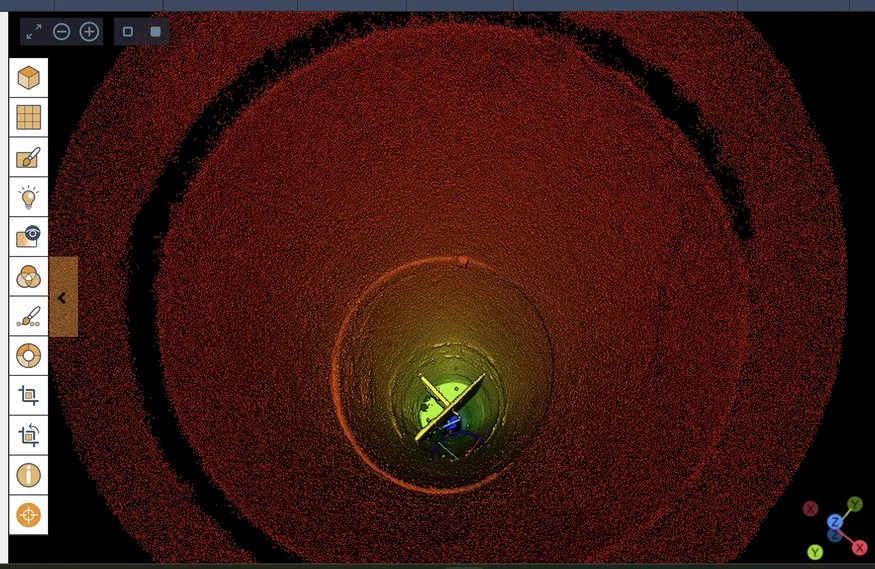

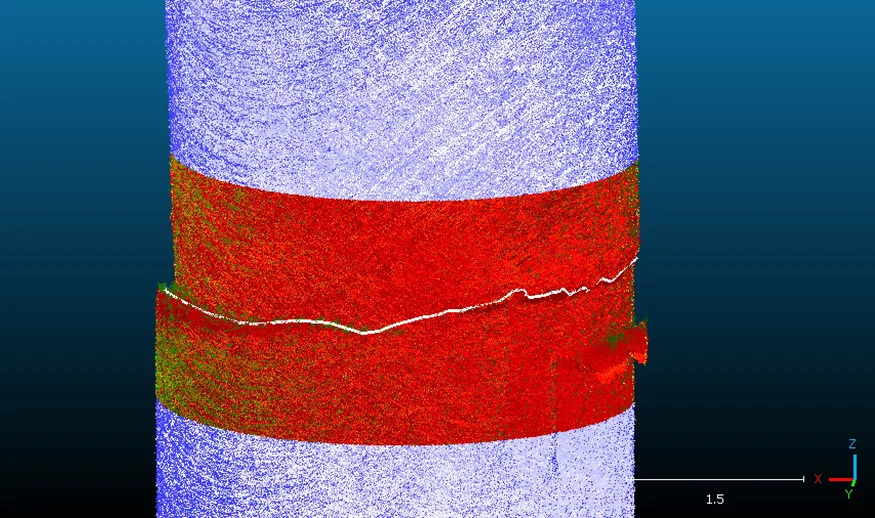

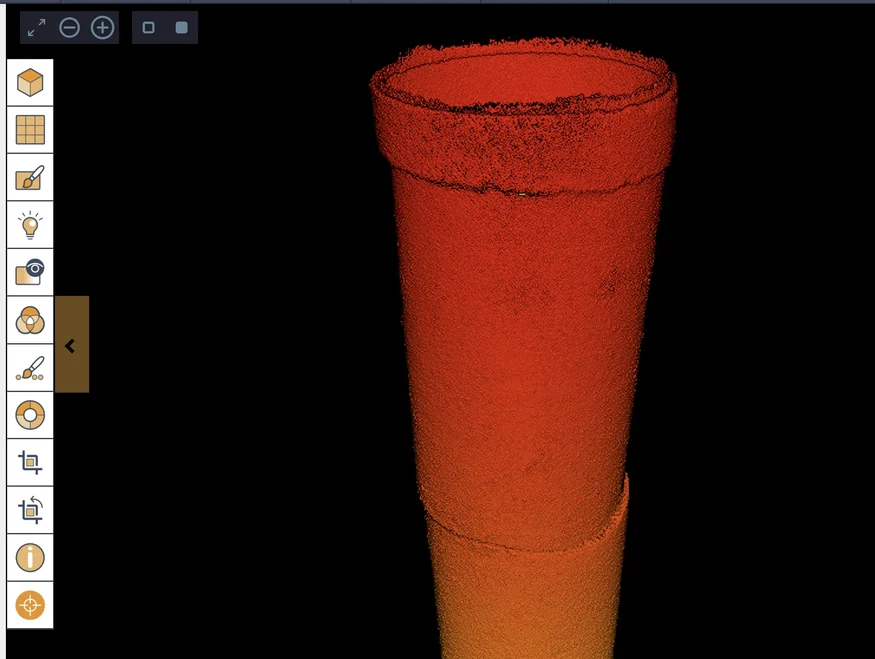

A cement plant recently discovered a visible fault in one of its 120-meter-high chimney towers. The issue couldn’t be ignored, but accessing such heights is always risky and often requires significant effort and resources. That’s where the Elios 3 came in. Within just one hour, it provided comprehensive 4K video footage and a detailed LiDAR scan, offering valuable insights for subsequent 3D analysis. Access Reaching such heights manually is hazardous and often necessitates crane operations. By deploying the Elios 3, the plant avoided the risks and expenses associated with cranes, completing the inspection efficiently in just an hour. Speed Traditional inspections might take a full day, but the Elios 3 completed the task in just an hour. This represents an efficiency improvement of up to 8 times over conventional methods. Cost Savings Using the Elios 3 instead of a crane saved the plant 30,000 euros that would have been spent on crane setup and dismantling over two days. Moreover, quick deployment minimized downtime, saving both time and money. Visualization The 3D model generated from the Elios 3 data enabled rapid decision-making and served as a valuable reference for future maintenance planning. In 2022 alone, global cement production reached 4.1 billion tons, making cement one of the most crucial construction materials worldwide. Any interruption in production could have severe consequences, impacting industries and infrastructure globally. Cement plants therefore face a delicate balancing act—meeting high demand while maintaining the integrity of their facilities. One critical component of cement production is the chimney stack, which releases hot gases from the kiln into the atmosphere. This stack is essential but rarely requires maintenance due to its robust design. However, should a fault occur, it could halt production entirely. When an engineer noticed a slight tilt at the top of the stack, immediate action was required to prevent potential hazards and ensure uninterrupted production. The chimney stack in question stood at 120 meters tall with a 4-meter diameter, connected to two kilns. Each kiln undergoes annual maintenance, staggered to avoid production halts. The stack serves as a conduit for gases up to 150°C, with an inner and outer concrete sleeve providing structural support against extreme heat. The interior of the chimney stack visualized with the Elios 3's LiDAR scan In February 2023, an anomaly was detected at the top of the stack. Concerned about potential structural failure, engineers decided to conduct a thorough inspection. Traditional methods would involve a crane setup, taking at least two days, with additional time required for the actual inspection. This approach is not only costly but also time-consuming, with crane-related expenses easily exceeding 30,000 euros. The plant’s drone operator was quickly mobilized. External observation proved inconclusive, so an enclosed-space drone capable of beyond-line-of-sight flights was needed—the Elios 3. Equipped with both visual and LiDAR capabilities, the drone aimed to gather comprehensive data for creating a detailed 3D model of the stack’s current state. Historically, such inspections required crane setups, consuming valuable time and resources. The Elios 3’s innovative cage design and integrated sensors allowed the drone to collect high-resolution imagery and precise LiDAR data. The drone pilot successfully completed the inspection in just one hour, with the stack cooling sufficiently within 1-2 hours for safe drone operation. This meant the plant could resume normal operations much sooner than anticipated. Post-flight, the LiDAR data was processed using GeoSLAM Connect 2.3, creating a high-density point cloud while accounting for any drift during the flight. The resulting LAS file was exported to CloudCompare for further analysis, allowing cross-sectional visualization of the stack. It became evident that the inner sleeve of the stack was subsiding in the uppermost 7-10 meters, with part of the concrete shifting 150mm eastward. This caused the top 7.5 meters of the stack to lean at a 4-degree angle. The 3D visualization revealed the extent of the damage, prompting swift action. With the drone’s findings, the plant’s leadership quickly shared the 3D model with relevant stakeholders. The recommended maintenance plan involved replacing the upper section of the inner concrete sleeve. The maintenance team responded swiftly: The maintenance crew successfully removed the damaged section, weighing seven tons, in five days. Cleaning and inspecting the outer tube followed, taking an additional day. Finally, the new section was installed within four days. The entire process took two weeks, showcasing the efficiency gains from drone inspections and the power of data-driven decision-making. Full visualization of the stack’s condition facilitated effective maintenance planning. The Elios 3 inspection yielded immediate cost savings, eliminating the need for crane setup and saving 30,000 euros. Its rapid deployment shaved at least two days off the usual workflow. The drone pilot noted the inspection was seamless, thanks to the LiDAR SLAM system aiding navigation inside the stack. Despite the distance, the drone’s signals remained stable, delivering clear results. Looking ahead, this project will serve as a case study for the cement industry, highlighting the importance of prompt action in addressing chimney stack faults. By cutting the inspection process by nearly three days, the Elios 3 ensured minimal disruption to production, reducing downtime to just two weeks. The expertise of the drone pilot and the efficiency of the Elios 3 made this project a success story for modern maintenance practices. Learn more about the Elios 3 and its diverse applications. Clutch Master Cylinder,Clutch Pump,Cylinder Clutch Master,Brake Clutch Master Cylinder ZHEJIANG BENTENG INTELLIGENT BRAKE SYSTEM CO.,LTD , https://www.cnnakol.comIdentifying Chimney Tower Faults Using the Elios 3 at a Cement Plant

Key Benefits in a Nutshell

Introduction

Understanding the Challenge

Implementing the Solution

Inspection Results

Drone Programs in Cement Plants