How the Elios 3 RAD payload is detecting radiation hotspots

WWSC Products,Fast Group In Workshop,Move to Workshop Place,Size and Figure Are Customized Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.comHow the Elios 3 RAD Payload is Detecting Radiation Hotspots

Key Benefits at a Glance

Nuclear power plants are subject to strict international and national safety standards. Continuous monitoring of all materials—from radioactive waste to coolant systems—is essential for maintaining the site’s overall safety certification. Drone inspections have become a game-changer in this field, significantly reducing the need for human presence in high-risk areas.

The Elios 3 drone has already proven its worth in the nuclear sector, with 80% of U.S. nuclear power plants using Flyability technology. The drone was tested under extreme conditions by the Idaho Environmental Coalition and the Department of Energy, where it was exposed to 10,000 R/h of radiation. Despite the harsh environment, the Elios 3 performed flawlessly, with its LiDAR, transmission, and lighting systems unaffected. This confirms that the drone is well-suited for radiation inspections.

Fast identification and measurement of radiation hotspots using the Elios 3 and new RAD payload.

Safe inspection without human intervention, scalable and repeatable across nuclear sites.

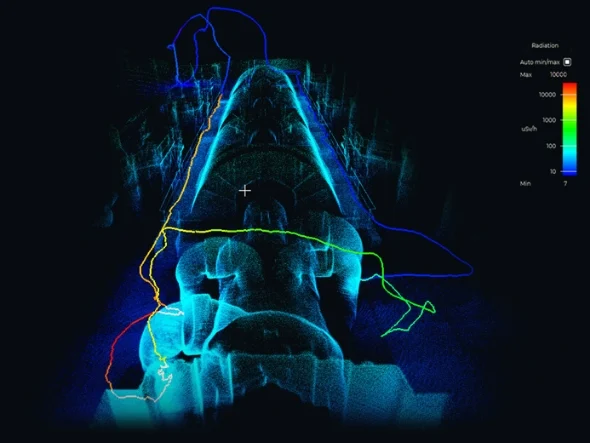

First-ever 3D model of nuclear power plant infrastructure created on this site.

Customer Needs

Elios was recently deployed at a major U.S. nuclear power plant as part of a trial to integrate the RAD payload into existing radiation inspection workflows. The goal was to find a reliable system for locating and measuring radiation hotspots. The plant managers wanted to compare the Elios 3 with a Telepole, a handheld sensor from Mirion that extends up to 11 feet (3.3 meters). Both tools are used for inspecting hard-to-reach areas, but the Elios 3 offers greater range and flexibility due to its remote operation.

Solution

The Elios 3 was deployed across multiple locations within the plant, equipped with the RAD payload. The RDS-32 WR sensor from Mirion provided real-time radiation data to the pilot, enabling immediate action if hotspots were detected.

“The addition of radiation detection capabilities to the drone allows us to perform surveys without exposing technicians to hazardous environments,†said the ALARA specialist. “It also helps us estimate exposure more accurately, not just in known high-dose areas, but in other difficult-to-access zones as well.â€

As the pilot received in-flight radiation readings, the team identified spikes indicating hotspots. Two high-dose areas were found in steam pipe bends, which were marked for further investigation.Conclusion

This new radiation inspection workflow proved highly effective, reaching areas that the Telepole couldn’t access due to its limited range. The collision-resistant design of the Elios 3 gave the pilot confidence to navigate through tight spaces on the turbine floor.

The team was particularly impressed by the quality and detail of the outputs. Creating a 3D model instead of a 2D map was a first for a radiation survey and represented a major step forward in visualizing radiation hotspots.

“Drone data is thorough and accurate, giving us high confidence that it reflects the true conditions in the field,†said the radiation protection technician.

Using drones for radiation surveillance not only reduces human exposure to radiation but also minimizes risks from industrial hazards. With 80% of U.S. nuclear power plants already using Flyability technology, the integration of the RAD payload is expected to become widespread. This innovation marks a new era in uncrewed, safe, and precise radiation monitoring.