How the Elios 3 RAD payload is detecting radiation hotspots

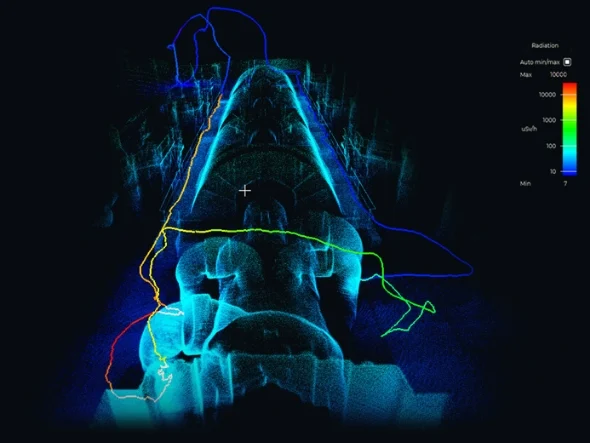

Fast identification and measurement of radiation hotspots using the Elios 3 and new RAD payload. Safe inspections with no human involvement, scalable and repeatable across sites. First-ever 3D model of nuclear power plant infrastructure created on this site. Nuclear power plants are subject to strict international and national safety regulations. Monitoring every material—whether it's nuclear waste or pipes carrying heavy water—is essential for maintaining the facility’s overall safety certification. Drone inspections have become a game-changer in this field by minimizing the need for human exposure, thereby enhancing safety standards. The Elios drone series has already proven its worth, with 80% of U.S. nuclear power plants using Flyability technology. These drones have passed rigorous testing, including a challenge from the Idaho Environmental Coalition and the Department of Energy, where the Elios 3 was exposed to 10,000 R/h of radiation. It handled the conditions effortlessly, proving its durability in high-radiation environments. The Elios 3 now features a specialized RAD payload developed by Mirion Technologies, a leader in radiation detection. This modular system allows the sensor to be attached for radiation surveys and easily swapped out for other payloads as needed. The RAD payload is used to detect, measure, and monitor radiological dose fields, providing critical data for decision-making. It measures both current radiation levels and cumulative exposure, offering more detailed information than a standard dosimeter. The Elios 3 RAD workflow delivers real-time, accurate data, along with flight path details and a 3D representation of the environment, making radiation surveys safer and more efficient. Elios was recently deployed at a major U.S. nuclear power plant as part of a trial to integrate the RAD payload into existing radiation inspection workflows. The goal was to find a reliable system for identifying and measuring radiation hotspots. Plant managers wanted to test the Elios 3 alongside a Telepole, a handheld sensor by Mirion that extends 11 feet (3.3 meters). Both tools are used for inspecting hard-to-reach areas, but the Elios 3 offers greater range due to its remote piloting capabilities. The areas inspected included the turbine deck and main steam lines, which are known for high radiation levels. If successful, this system could become the standard for radiation inspections at the plant and potentially across the entire nuclear fleet under the parent company’s control. An ALARA specialist, a radiation protection technician, and the plant’s drone coordinator collaborated to implement the Elios 3 RAD test during a nuclear outage. The Elios 3 was deployed across multiple locations within the plant, equipped with the RAD sensor. The RDS-32 WR sensor from Mirion transmitted real-time data back to the pilot. The ALARA specialist highlighted the benefits: “Adding radiation detection to the drone allows us to survey hazardous areas without exposing technicians to risk. It also helps us estimate exposure more accurately before starting work, not just in known high-dose zones, but in other hard-to-reach spots as well.†As the pilot received in-flight radiation readings, the team identified spikes indicating hotspots. Two high-dose areas were found in pipe bends of the steam system, which were flagged for further investigation. After the flights, the data was processed using Flyability’s Inspector 4.0 software, generating graphs and 3D models. These visualizations allowed plant managers and the parent company to clearly see the radiation hotspots in the steam pipe bends, giving inspectors a better understanding of the situation. This new radiation inspection workflow proved to be highly effective, reaching areas that the Telepole couldn’t access thanks to the Elios 3’s extended range. The collision-resistant design gave pilots confidence to navigate through the turbine area safely. The team was impressed with the level of detail and quality from the output. Creating a 3D model instead of a 2D map was a first for a radiation survey and marked a significant advancement in visualizing radiation hotspots. “The drone data is thorough and accurate, giving us high confidence that it reflects the true conditions in the field,†said the radiation protection technician. Using drones for radiation surveillance reduces unnecessary exposure to both radiation and industrial hazards. The plant’s parent company is already seeing the benefits of drone and robot use across their infrastructure, and the addition of the RAD payload enhances these advantages even further. With the Elios 3 and RAD payload, accurate, uncrewed radiation surveys are now possible. Given that 80% of U.S. nuclear power plants already use Flyability technology, this workflow is set to be adopted nationwide and beyond, marking a major step forward in nuclear safety and efficiency. Packaging System,Movable In Different Industry,Sample Solution in Limited Area,Small Group for Limit Invest Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.comHow the Elios 3 Rad Payload is Detecting Radiation Hotspots

Key Benefits at a Glance

Customer Needs

Solution

Conclusion