In recent years, the demand for environmental pollution prevention and control has surged significantly, driving rapid growth in the environmental protection machinery manufacturing industry. The average annual output value of the sector has risen by over 15%, with some key companies reporting increases as high as 37%. In 2006, the production of water pollution control equipment saw a sixfold increase compared to the previous year, while solid waste treatment equipment output grew by 31.18%. Environmental monitoring equipment reversed its negative growth trend from 2005, but air pollution control equipment experienced a 19.64% decline. Meanwhile, exports of environmental protection equipment have continued to grow rapidly, although import volumes still exceed export values.

Currently, the most active areas in the domestic environmental protection market include urban sewage treatment equipment, recycled water reuse systems, flue gas desulfurization and denitrification equipment for coal-fired power plants, municipal solid waste treatment systems, and hazardous waste (including medical waste) treatment solutions. With the development of a circular economy, the comprehensive utilization of resources is expected to accelerate, creating new opportunities for the environmental machinery industry. Other emerging fields include the recycling of electronic waste, control of micro-pollutants in drinking water, management of volatile organic compounds, soil pollution prevention, and clean production technologies—each presenting significant potential for future growth.

Looking ahead, the chemical environmental protection equipment industry must focus on developing and promoting targeted technical solutions. This will not only align with China’s broader push toward green chemical production but also open up new avenues for company expansion. However, compared to developed countries, China still lags in several critical areas, such as high-concentration, hard-to-biodegrade organic wastewater treatment, advanced incineration technologies, high-efficiency biochemical strains, and monitoring instrumentation. Due to the wide variety of pollutants generated by chemical processes, no single method can effectively address all issues. As a result, there is an urgent need to improve the performance of existing environmental protection equipment and increase the share of high-tech, complete-system solutions.

To support this, the government has identified several key environmental equipment types that will be encouraged in the future. These include dry flue gas desulfurization systems with a calcium-to-sulfur ratio below 1.4 and a desulfurization rate of at least 75%, high-temperature bag filters capable of operating at 250°C with dust removal efficiency exceeding 99%, and efficient electrostatic precipitators with capacities ranging from 30,000 to 1 million cubic meters per hour. Other important technologies include ozone generators with improved energy efficiency and reduced costs, as well as advanced wastewater treatment systems like high-efficiency dissolved air flotation units and SBR reactors.

In the solid waste treatment sector, circulating fluidized bed boilers are being promoted for their ability to handle low-quality fuels, while low-nitrogen burners help reduce emissions. Waste heat recovery systems, energy-efficient fans, and fly ash separation equipment are also gaining traction. Additionally, waste rubber cracking and carbon black recovery systems are becoming increasingly important in industrial settings.

It is widely recognized that the chemical industry is one of the largest sources of industrial pollution. According to the 2006 Environmental Statistics Annual Report, chemical wastewater discharge accounted for 19% of total industrial wastewater, making it the leading contributor. Similarly, chemical emissions ranked third in total sulfur dioxide and dust, while cyanide, petroleum, sulfide, and arsenic emissions were the highest. These environmental challenges continue to pose significant barriers to the sustainable development of the chemical sector, emphasizing the urgent need for more effective pollution control measures.

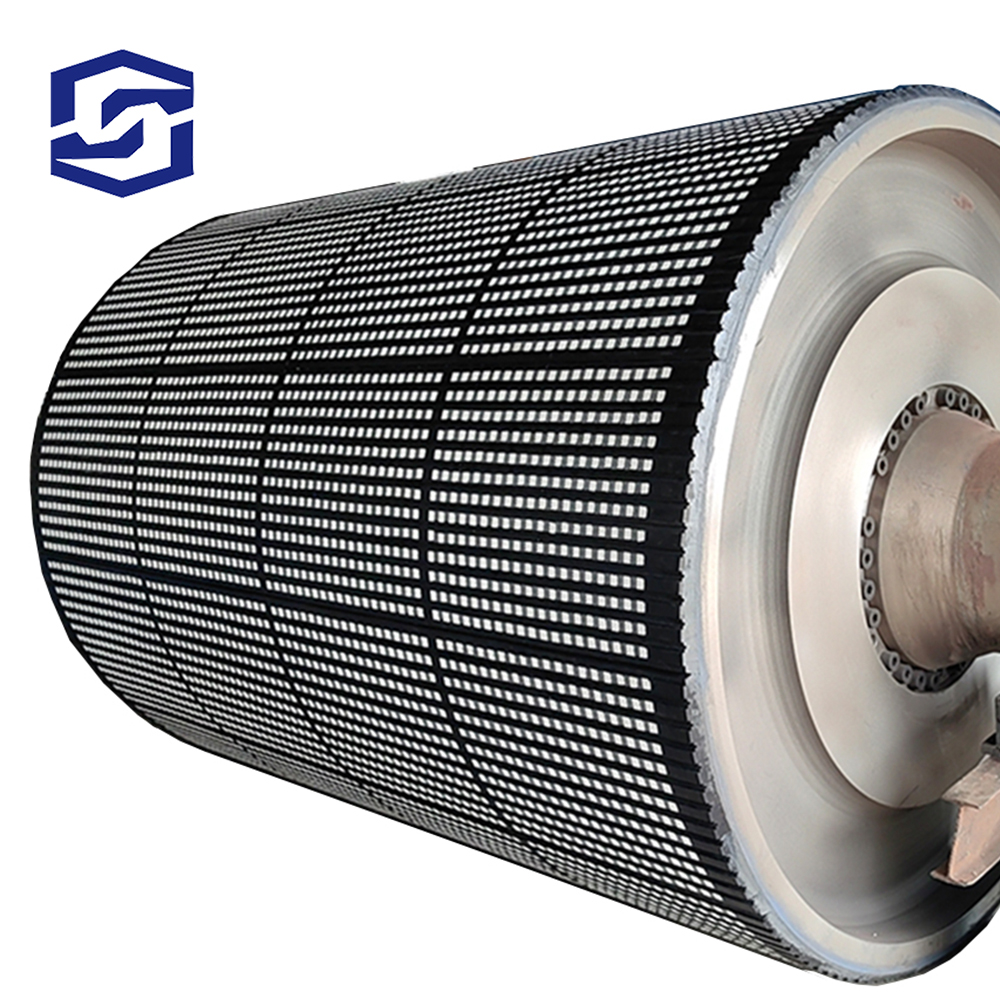

Roller Covered Ceramic Rubber Sheet

Roller covered ceramic rubber sheet is a way of cold vulcanization of roller covering, the surface of the ceramic piece can play a non-slip role, to extend the service life of the conveyor belt roller, each piece of ceramic piece is spaced at a certain distance, which can make the roller on the discharge of foreign matter,gives the drum a unique self-cleaning feature that is especially suited to wet working environments.

The combination of ceramic and rubber sheet increases the wear resistance of rubber sheet,making our ceramic rubber sheets more durable and longer lasting than ordinary rubber sheets.

The CN layer on the back side acts as a super Adhesive, the ceramic rubber sheet is more effective when used with our Adhesive!

Due to the multiple performance advantages of ceramic rubber sheets, they are now widely used in belt conveyor rollers in coal mines, grain silos, iron and steel, chemical fertilisers, cement factories, power plants, harbours, wharves and many other industries.

If your belt conveyor roller equipment is not durable, come and have a look our ceramic rubber plate, you will have an efficient, stable and environmentally friendly conveying solution. Our ceramic rubber sheet is not only a product, but also a powerful assistant for you to improve the competitiveness of your enterprise and achieve industrial upgrading.

Come and contact us to start your excellent conveying journey and make the future production road smooth and unobstructed!

ceramic rubber plate,belt conveyor roller covering ceramic rubber sheet,Roller covered ceramic rubber sheet,Wear resistant ceramic rubber sheet,ceramic rubber lagging

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com