In recent years, the demand for environmental pollution prevention and control has surged significantly, driving remarkable growth in the environmental protection machinery manufacturing industry. The average annual industrial output value of the sector has increased by over 15%, with some key enterprises experiencing growth as high as 37%. In 2006, the production of water pollution control equipment saw a sixfold increase compared to the previous year, while solid waste treatment equipment output rose by 31.18%. Environmental monitoring equipment also reversed its negative growth trend from 2005, although air pollution control equipment experienced a slight decline of 19.64%. Meanwhile, exports of environmental protection equipment have continued to grow rapidly, though imports still exceed export values.

Currently, the most active areas in the domestic environmental protection market include urban sewage treatment equipment, recycled water reuse systems, flue gas desulfurization and denitrification equipment for coal-fired power plants, municipal solid waste treatment systems, and hazardous waste (including medical waste) treatment facilities. With the development of a circular economy, resource recycling and comprehensive utilization technologies are expected to become a new frontier with significant potential for environmental machinery manufacturing. Additional opportunities lie in the recycling of electronic waste, controlling micro-pollutants in drinking water, managing volatile organic compounds, preventing soil contamination, and promoting clean production methods.

Looking ahead, the chemical environmental protection equipment industry should focus on developing and promoting targeted technologies that align with China’s green development goals. This will not only support the broader shift toward sustainable chemical production but also open up new growth opportunities for companies within the sector.

Compared to developed countries, China still lags in certain advanced environmental protection technologies, particularly in the treatment of high-concentration, hard-to-biodegrade organic wastewater, incineration processes, and the application of high-efficiency bio-treatment strains. Monitoring instrumentation and other critical areas also require improvement. Due to the wide variety of pollutants generated by chemical production, no single method can effectively address all challenges. Therefore, the performance of major domestic environmental protection equipment must continue to be optimized.

To meet future needs, the industry should increase the proportion of high-tech products and large-scale technical equipment, advance key technological innovations, and develop cost-effective, high-efficiency environmental protection solutions tailored for the chemical industry.

Among the government-supported environmental equipment in the coming years, several are particularly relevant to the chemical sector. These include dry flue gas desulfurization units with a calcium-to-sulfur ratio below 1.4 and a desulfurization rate of at least 75%, high-temperature bag filters capable of operating at 250°C with a dust removal efficiency of over 99%, and efficient electrostatic precipitators with processing capacities ranging from 30,000 to 1 million cubic meters per hour.

Other key equipment includes sewage treatment rotary grid systems with improved efficiency and reduced costs, oil recovery machines, high-efficiency air flotation systems, and advanced ozone generators designed for wastewater treatment. Solid waste treatment technologies such as circulating fluidized bed boilers and low-nitrogen burners are also being promoted to reduce emissions and improve energy efficiency.

As one of the main sources of industrial pollution, the chemical industry faces serious environmental challenges. According to the 2006 Environmental Statistics Annual Report, it accounts for 19% of total industrial wastewater discharge, 7% of exhaust emissions, and 7% of solid waste generation. Sulfur dioxide and dust emissions rank among the highest, and pollutants like cyanide, petroleum, and heavy metals are also major concerns. These environmental issues continue to pose barriers to the long-term sustainable development of the industry.

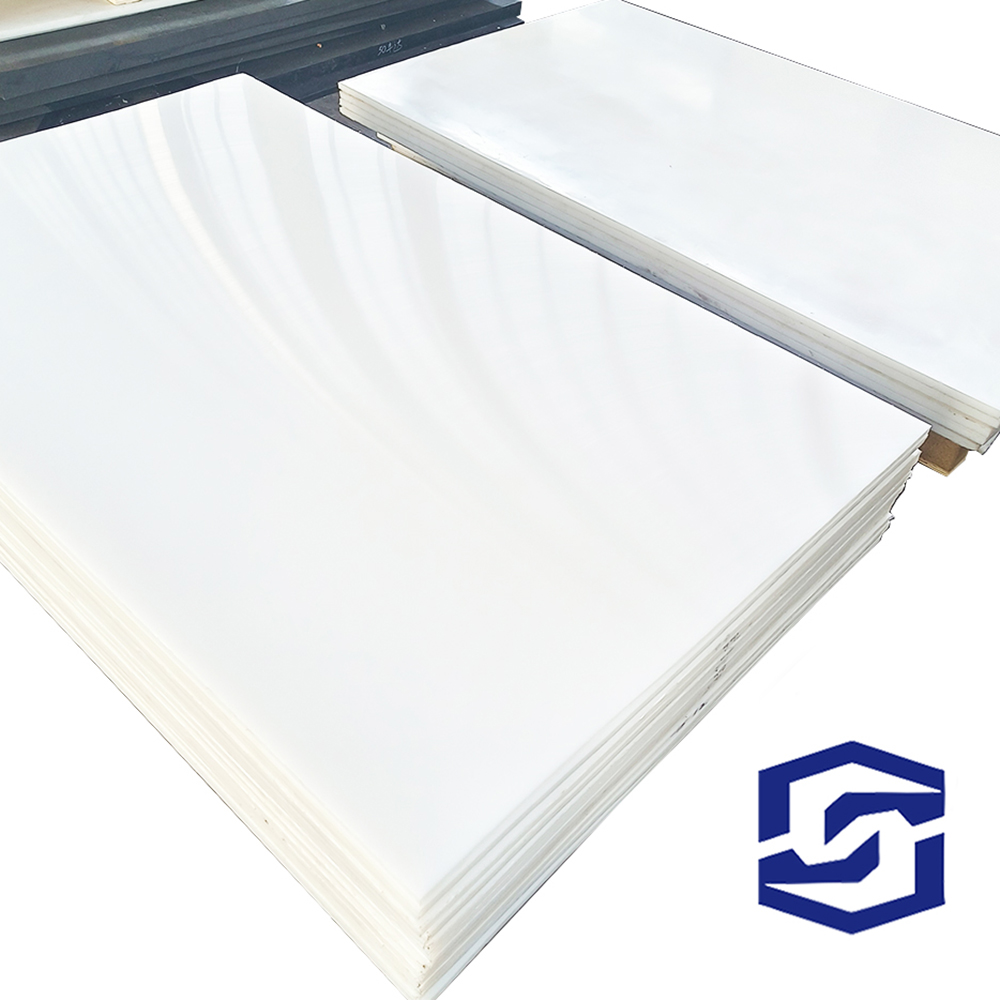

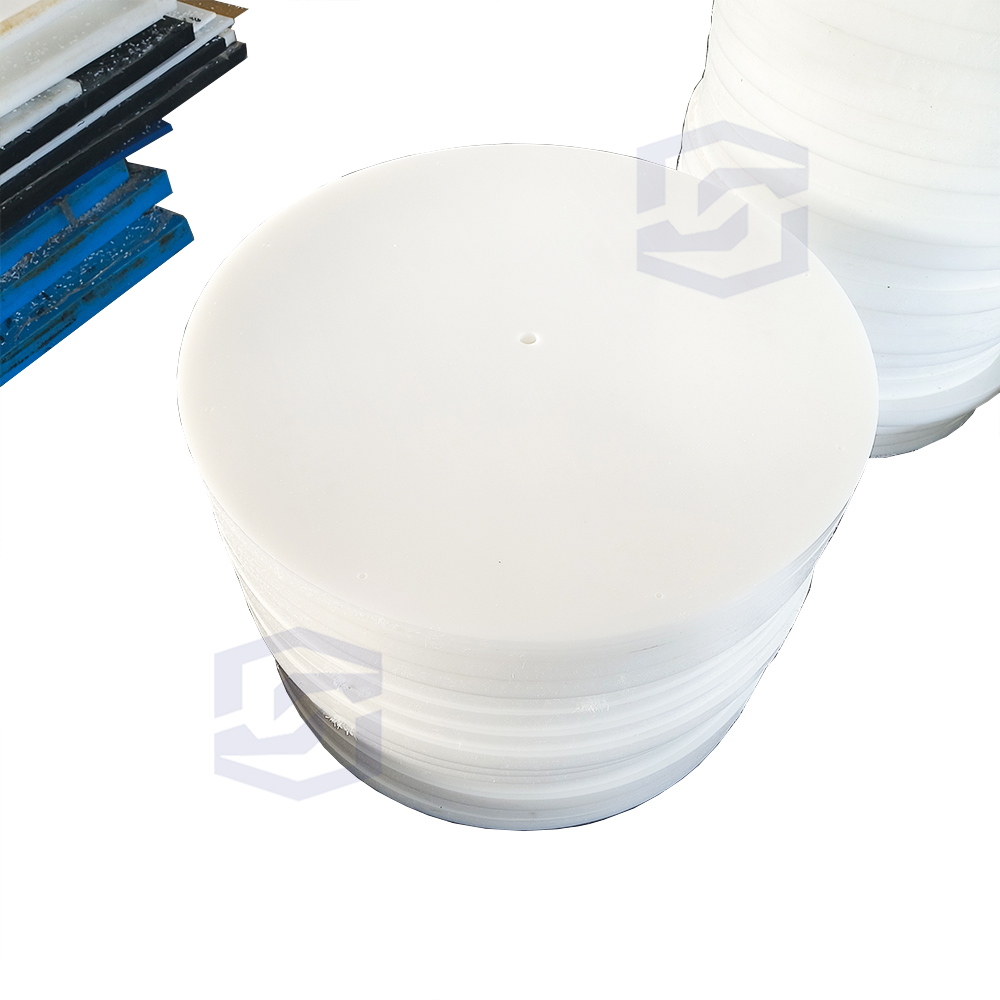

Engineering Plastic

Ultra-high molecular weight polyethylene linerboard also known as UHMWPE liners, is a thermoplastic engineering plastics with molecular weight up to more than 3 million, it has good anti clogging, self-lubricating, non absorbent, high wear resistant, corrosion resistant, it has been widely used in coal, electric power, cement, metallurgy, and other industries in the raw coal silo, clay silo, iron silo, mixing silo, and other kinds of silos.

The product can completely solve the silo, hopper, mine chute, chute, storage boxes and other warehouse wall of the sticky material, stick to the wall, blocking material and other serious impact on the production of the problem.

Â

UHMWPE liner,Wear resistant UHMWPE liner plate,UHMWPE sheets,engineering plastics,high performance

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com